Reinke & Schomann, Inc. is a leading manufacturer that offers custom-fabricated steel materials. With over 90 years of being in the industry, we have the in-house capabilities and expertise to meet all your custom steel fabrication needs. Our superior steel manufacturing services focus on quality and not quantity to provide superb customer satisfaction and enhance customer experience.

Reinke & Schomann, Inc. is the one-stop shop for all your custom steel fabrication projects related to your conveyor needs. With the proper method and equipment, we can fabricate any steel material you need for the product you’re looking for. We pride ourselves on our quality control measures that ensure all our products meet the highest standards.

What is custom steel fabrication?

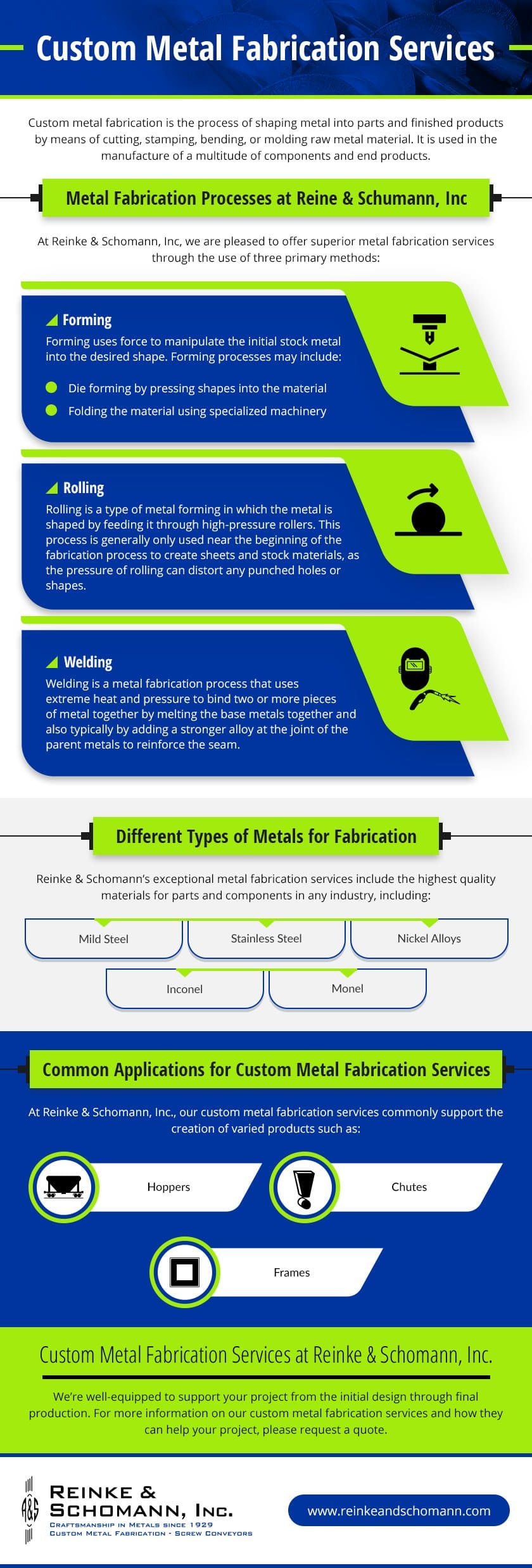

Custom steel fabrication is the process of different methods of shaping steel components and parts into finished products. It can be through bending, cutting, stamping, and molding raw steel material. Finished products are used in a variety of applications in various industries.

Our custom steel fabrication service is different because we use superior methods to achieve the desired results. With our quality over-quantity mindset, we can exceed your expectations. We also have a team of experts that are passionate about their work and take pride in every project they complete.

Moreover, we use only the best materials to ensure that each project is built with quality in mind. We specialize in stainless steel, aluminum, steel, and abrasion-resisting steel. All of these materials are chosen for their strength, durability, and ability to withstand extreme conditions.

Why use stainless steel for metal fabrications?

Stainless steel is an iron-based alloy, a prevalent choice among fabricators. It offers myriad benefits, such as its resistance to heat and staining. Stainless steel also has 10.5% chromium, which makes it resistant to corrosion. Additionally, it’s durable and low maintenance.

Some frequent alloying elements in stainless steel are nickel, magnesium, molybdenum, and nitrogen. Depending on the application, different alloys offer distinct advantages.

Advantages of using stainless steel for custom fabrication

Using stainless steel for custom fabrication offers tons of benefits. Some of these are:

- Versatility: Can be used for various applications, such as food processing, chemical storage, and medical equipment.

- Aesthetics: Provides a clean and modern look.

- Strength: Able to maintain its shape and structure under extreme conditions.

- Low maintenance: Easy to clean and requires little upkeep

- Long-lasting: It’s resistant to corrosion, staining, and heat.

If you choose stainless steel, you’ll be sure to receive durable end products that will last a long time without the need to replace or maintain them.

How is custom steel fabrication done?

At Reinke & Schomann, Inc., we use three standard steel fabrication methods. We decide on the technique depending on the client’s requirements and what they want to achieve. They are forming, rolling, and bending.

Cutting

Custom steel fabrication involves cutting to create custom structures, parts, and products. It utilizes high-def plasma, laser, sheering, and sawing processes.

- High Def Plasma cutting uses a powerful electrical gas stream to accurately cut materials such as steel plates and shapes. The machine is guided by CAD software to ensure precise results.

- Laser cutting is used for intricate cuts that require pinpoint accuracy with minimal material distortion. This process melts the material with a beam of concentrated light, allowing for more complex shapes than traditional methods.

- Shearing is often used for large sheets of flat stock or wide bars of material where straight lines are required, such as in the production of boxes, frames, or any other item that requires a rectangular shape. The shear cuts the material along a straight line in one single motion and can be used for long pieces of material such as steel sheets or bars.

- Sawing is used to cut large amounts of material into smaller parts or components. It utilizes cutting blades with teeth to carve out desired shapes from metal materials such as steel plates, sheet metal, and round bar stock.

Forming and Rolling

Forming is a method that many fabricators commonly use to achieve the desired shape. With forming, force is used to manipulate the material and get it into the shape you want. It also has a similar process to bending, where metal forming processes may include machining or folding.

- Pressing shapes into the material for die forming

- Using a special machine to fold a material

On the other hand, rolling is where the steel material is fed through high-pressure rollers. It shapes the metal according to the specifications of the client. But we only use this method at the beginning of the operation to create sheets and stock materials. It’s because there’s a possibility that the pressure of the rolling can distort the punched shapes.

Welding

The most commonly used metal fabrication process is welding, which involves using extreme heat and pressure to bind two or more metal pieces together. We also add a stronger alloy at the joint of the parent metals to reinforce the seam.

Common industry applications for custom steel fabrication

Custom steel fabrication is made in a wide range of applications, such as:

- Medical applications: The stainless steel’s biocompatibility and hygienic characteristics provide the necessary properties used in medical tools and instruments.

- Food-processing: Stainless steel is commonly used to manufacture products used in food processing and other equipment used for the industry.

- Construction: Buildings mostly have stainless steel parts due to their high strength and incredibly corrosion-resistant capabilities.

- Transportation: Automotive, aerospace, rail, and marine industries rely on stainless steel parts and components.

Benefits of opting for custom steel fabrication services

Custom steel fabrication is integral to every project, big or small. Since it’s used in various applications in numerous industries, it’s best to choose custom fabricating stainless steel to achieve a smooth and seamless result.

Here are some reasons why you should opt for our custom steel fabrication service:

- The product is made to your specifications, mainly if you use it for a specific project or application. You receive a product according to your design and style, and it’s precisely what you want for what you intended to use it for.

- We can work with steel, stainless steel, aluminum, and abrasion-resistant materials.

- Custom steel fabrication from Reinke & Schomann, Inc. offers long-lasting results to any project. Its durability allows it to withstand any environment and will surely last for many years.

- Steel-fabricated products can be used in large and small-scale projects.

- Opting for custom steel fabrication means you will receive high-quality products. Since the metal is high-quality, the methods we use to fabricate them are also some of the best, with no inconsistencies compared to mass-produced items.

Custom steel fabrication services by Reinke & Schomann, Inc

Our custom steel fabrication services are open to all clients from various industries. With almost 90 years of experience, we are the leading custom manufacturer you can trust. Furthermore, we ensure to support your project with skilled and hardworking staff that has advanced knowledge in:

- Using CNC press brakes

- High-definition plasmas

- Welding equipment

- Angle, bar, and plate rolling equipment

Our expertise enables us to handle your orders and support your projects from start to finish. While working with you, we’ll help you with the design until you receive the desired product with the specs you requested.

We’re a trusted & leading steel manufacturer that puts quality over quantity

Custom steel fabrication services provide tons of benefits, which customers can take advantage of. Whether you’re looking for quality metalwork for your business projects, we can take care of it. We provide excellent results with every custom steel fabrication service that will last many years.

Reinke & Schomann, Inc. is capable of meeting your needs, especially when it comes to specific requirements. With our incredible customer service, you will receive a product that will pass your standards. We ensure that the quality of our work is at its best so you can have peace of mind.

So don’t hesitate to contact us if you have questions about our service. Or you may request a quote today.

Reinke & Schomann, Inc. offers custom metal fabrication services for clients in various industries including food processing, mining, waste water treatment, and waste processing among others. In addition, we offer complete fabrication services of conveyor systems. We specialize in forming, rolling, and welding processes to manufacture mild steel, stainless steel, nickel alloys, Inconel, and Monel into customer specified profiles. Parts are possible up to 16′ (4877mm) in diameter and up to 1″ (25.4mm) thick, with tight tolerances held throughout fabrication. Typical applications include fabrication for hoppers, tanks, chutes, and frames. Parts are abrasion, corrosion, and heat resistant according to the customer requirements.

All production takes place in our state of the art, 20,000 sq. foot facility, upholding the highest standards set by leading industry regulatory boards including ANSI, ASME, and ASTM. All products are subject to our comprehensive testing measures for quality and integrity. We produce high quality metal parts with impressive lead times, handling low production volume levels. To learn more about our custom metal fabrication services or our other manufacturing capabilities, please see the table below or contact us directly.

Showcased Projects

Reinke & Schomann, Inc. compiled a few selected project examples which demonstrate our capabilities and services. Click on the links below to view more information about the project.

Metal Fabrication Capabilities

- General Fabrication Capabilities

-

- Sheet metal and plate fabrication up to 1 inch thick in carbon and stainless steels

- Applications

-

- Hoppers

- TanksChutes

- Frames

- Construction Material

-

- Abrasion Resistant Alloys

Hastelloy - Inconel

Mild SteelMonel - Nickel Alloys

Stainless Steels

- Abrasion Resistant Alloys

- Characteristics/Features

-

- Forming

Rolling - Welding

Tabs - High Definition Plasma Cutting (up to 2” Stainless)

- Forming

- Resistances

-

- Abrasion

- Corrosion

- Heat

- Finishing

-

- Galvanizing

- Diameter

-

- 16 ft. / 4877mm

- Thickness

-

- Max: 1 in. / 25.4 mm

- Tolerance (+/-)

-

- Industry accepted practices

- Production Volume

-

- Low Volume Custom

- Industries Served

-

- Centrifuges

Waste Water Treatment

Cement

Chemical - Dewatering

Food Processing

Industrial

Pulp & Paper

Waste Processing - Art

Water Kiln

Food

- Centrifuges

- Industry Standards Met

-

- CEMA Compliant

AWS Compliant Welding

ANSI - American National Standards Institute ASME

American Society of Mechanical Engineers - ASTM

American Society for Testing and Materials

- CEMA Compliant

- File Formats Accepted

-

- AutoCAD (DWG)

BMP

Bit Mapped Graphics

DXF

Drawing Interchange Format, or Drawing Exchange Format - GIF

Graphics Interchange Format

JPG or JEPG

Joint Photographic Experts Group - PDF

Portable Document Format

TIFF

Tagged Image File Format

- AutoCAD (DWG)