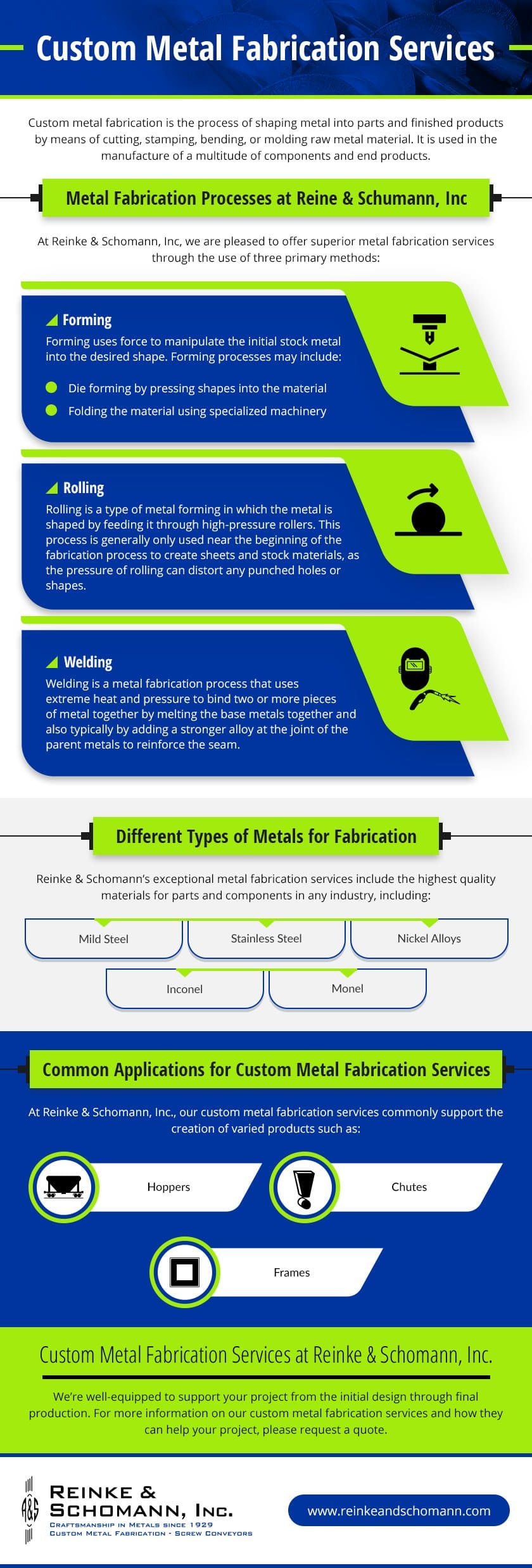

Custom metal fabrication is the process of shaping metal into parts and finished products by means of cutting, stamping, bending, or molding raw metal material. It is used in the manufacture of a multitude of components and end products.

Metal Fabrication Processes at Reinke & Schomann, Inc

At Reinke & Schomann, Inc, we are pleased to offer superior metal fabrication services through the use of three primary methods:

Forming

Forming uses force to manipulate the initial stock metal into the desired shape. Forming processes may include:

-

- Die forming by pressing shapes into the material

- Folding the material using specialized machinery

Forming processes typically require a great deal of pressure and are performed by specialized machinery tailored to each individual forming process.

Rolling

Rolling is a type of metal forming in which the metal is shaped by feeding it through high-pressure rollers. This process is generally only used near the beginning of the fabrication process to create sheets and stock materials, as the pressure of rolling can distort any punched holes or shapes.

Welding

Welding is a metal fabrication process that uses extreme heat and pressure to bind two or more pieces of metal together by melting the base metals together and also typically by adding a stronger alloy at the joint of the parent metals to reinforce the seam.

Different Types of Metals for Fabrication

Reinke & Schomann’s exceptional metal fabrication services include the highest quality materials for parts and components in any industry, including:

Mild Steel

Mild steel, or low carbon steel, is an iron alloy that is more easily welded and machinable than other types of steel with higher carbon contents. The lower carbon content of mild steel makes it easier to use in metal fabrication processes but possesses less overall tensile strength than some other steel.

Due to its high iron content, mild steel is magnetic and may be prone to rust if it is not properly coated. Mild steel is used in a variety of applications, including furniture, automobile parts, fencing, and structural steel.

Stainless Steel

Stainless steel is an iron alloy manufactured with a higher level of chromium, which creates a natural passive layer of oxidation on the surface of the steel to protect it from corrosion. Stainless steel is frequently used for workspace surfaces, household appliances, surgical and medical equipment, and piping, among many other applications.

Nickel Alloys

Nickel alloys are particularly useful for their resistance to heat and corrosion and are therefore used in a number of applications in which high temperatures and chemical exposure are frequent, such as nuclear power plants, petrochemical processing facilities, and aircraft engines. Nickel bonds easily with other metals to form stable and versatile alloys with a variety of attributes, including:

- Electrical resistance

- Low expansion

- Magnetism

Inconel

Inconel a very strong nickel-chromium alloy prized for its high resistance to pressure and extreme heat. It is also resistant to corrosion from saltwater, which makes it an ideal option for use in extreme marine environments. Inconel is an expensive alloy that’s generally employed in specialized applications for which other alloys cannot be used, such as jet engines and nuclear reactors.

Monel

Monel is a strong nickel-copper alloy trademarked by Special Metals Corporation. It is best known for its resistance to corrosion and is frequently used in marine engineering. In addition to corrosion and acid resistance, Monel has low heat expansion and is stronger than steel but remains malleable. Beyond marine applications, it sees use in heat exchangers, pumps, and chemical processing equipment.

Common Applications for Custom Metal Fabrication Services

At Reinke & Schomann, Inc., our custom metal fabrication services commonly support the creation of varied products such as:

-

- Hoppers

- Chutes

- Frames

Custom Metal Fabrication Services at Reinke & Schomann, Inc.

With 90 years of experience, Reinke & Schomann, Inc. is proud to be a leader in custom metal fabrication services. Our highly knowledgeable staff is thoroughly trained in the use of:

- High-definition plasmas

- CNC press brakes

- Angle, bar, and plate rolling equipment

- Welding equipment

We’re well-equipped to support your project from the initial design through final production. For more information on our custom metal fabrication services and how they can help your project, please request a quote.

Reinke & Schomann, Inc. offers custom metal fabrication services for clients in various industries including food processing, mining, waste water treatment, and waste processing among others. In addition, we offer complete fabrication services of conveyor systems. We specialize in forming, rolling, and welding processes to manufacture mild steel, stainless steel, nickel alloys, Inconel, and Monel into customer specified profiles. Parts are possible up to 16′ (4877mm) in diameter and up to 1″ (25.4mm) thick, with tight tolerances held throughout fabrication. Typical applications include fabrication for hoppers, tanks, chutes, and frames. Parts are abrasion, corrosion, and heat resistant according to the customer requirements.

All production takes place in our state of the art, 20,000 sq. foot facility, upholding the highest standards set by leading industry regulatory boards including ANSI, ASME, and ASTM. All products are subject to our comprehensive testing measures for quality and integrity. We produce high quality metal parts with impressive lead times, handling low production volume levels. To learn more about our custom metal fabrication services or our other manufacturing capabilities, please see the table below or contact us directly.

Showcased Projects

Reinke & Schomann, Inc. compiled a few selected project examples which demonstrate our capabilities and services. Click on the links below to view more information about the project.

Metal Fabrication Capabilities

- General Fabrication Capabilities

-

- Sheet metal and plate fabrication up to 1 inch thick in carbon and stainless steels

- Applications

-

- Hoppers

- TanksChutes

- Frames

- Construction Material

-

- Abrasion Resistant Alloys

Hastelloy - Inconel

Mild SteelMonel - Nickel Alloys

Stainless Steels

- Abrasion Resistant Alloys

- Characteristics/Features

-

- Forming

Rolling - Welding

Tabs - High Definition Plasma Cutting (up to 2” Stainless)

- Forming

- Resistances

-

- Abrasion

- Corrosion

- Heat

- Finishing

-

- Galvanizing

- Diameter

-

- 16 ft. / 4877mm

- Thickness

-

- Max: 1 in. / 25.4 mm

- Tolerance (+/-)

-

- Industry accepted practices

- Production Volume

-

- Low Volume Custom

- Industries Served

-

- Centrifuges

Waste Water Treatment

Cement

Chemical - Dewatering

Food Processing

Industrial

Pulp & Paper

Waste Processing - Art

Water Kiln

Food

- Centrifuges

- Industry Standards Met

-

- CEMA Compliant

AWS Compliant Welding

ANSI - American National Standards Institute ASME

American Society of Mechanical Engineers - ASTM

American Society for Testing and Materials

- CEMA Compliant

- File Formats Accepted

-

- AutoCAD (DWG)

BMP

Bit Mapped Graphics

DXF

Drawing Interchange Format, or Drawing Exchange Format - GIF

Graphics Interchange Format

JPG or JEPG

Joint Photographic Experts Group - PDF

Portable Document Format

TIFF

Tagged Image File Format

- AutoCAD (DWG)