Types of Ribbon Screw Conveyors

Leave a CommentReinke & Schomann has been a leading manufacturer of high-quality custom ribbon flight screw conveyors for over nine decades. We serve a wide range of industries, providing them with top-tier metal components for their assemblies.

One of our services is manufacturing custom-made ribbon flight screw conveyor parts in low volumes for our clients. Our focus is more on quality and customer service for an exceptional customer experience.

What is a ribbon flight?

Ribbon flights are used in ribbon screw conveyors to mix and blend bulk materials. Their profile makes them ideal for mixing sticky or dense materials.

We can produce non-standard sizes of up to 18′ (5486mm) in diameter, lengths up to 60′ (18,300mm), and thicknesses up to 1.5″ (38.1mm). We ensure to fabricate each with tight tolerances exceeding CEMA standards.

Ribbon Flight Screw Conveyor System, Components, & Parts

A ribbon flight screw conveyor is recommended for mixing or handling sticky materials. We offer custom ribbon flights and custom screw conveyors, depending on the needs and specifications of the customer.

The ribbon flights are applicable in equipment mixers, spiral let-down chutes, blender blades, stack strakes, and more. Ribbons are used for machine tools, bulk material handling, waste processing, water treatment, food processing, metal chip removal, sludge conveyors, and many more applications.

Both ribbon flights and screw conveyor custom parts are available in various metals, including:

- Mild steel

- Stainless steel

- Monel

- Inconel

- Hastelloy

- Abrasion-resistant alloys

- Nickel alloys

The Ribbon Screw Conveyor Design

The ribbon screw conveyor is a special type of screw conveyor designed to handle sticky or viscous materials. The ribbon screw has a series of flights, or blades, that are mounted on the shaft so that they overlap.

Three types of ribbon flight conveyor screws:

Integral Leg Ribbon Screw

It utilizes the post as part of the ribbon flighting. In addition, it’s the most commonly used design for conveying sticky materials. It’s also cost-effective to manufacture or fabricate compared to post-type ribbon screws.

Post Type Ribbon Screw

It uses round bar posts and ribbon flighting. It’s designed to have less surface area for the bulk material to stick to, which makes it perfect for conveying sticky bulk material. Additionally, it’s easier to replace the ribbon if needed.

Double Flight Ribbon Screw

We can design it for mixing dry materials. But it’s also ideal for conveying sticky materials while providing a more uniform discharge. It has an outer ribbon with an inner ribbon flight with a small diameter. The materials move back and forth because both flights are designed to be opposite-handed.

Manufacturing custom ribbon flight screw conveyors with a focus on quality & customer service

We offer quality customized ribbon flight screw conveyor parts and components for specific applications and assemblies. No matter what industry you’re in, we can serve you.

Reinke & Schomann prioritizes quality over quantity, so we create low volumes according to the needs of our customers. Don’t hesitate to contact us or request a quote today.

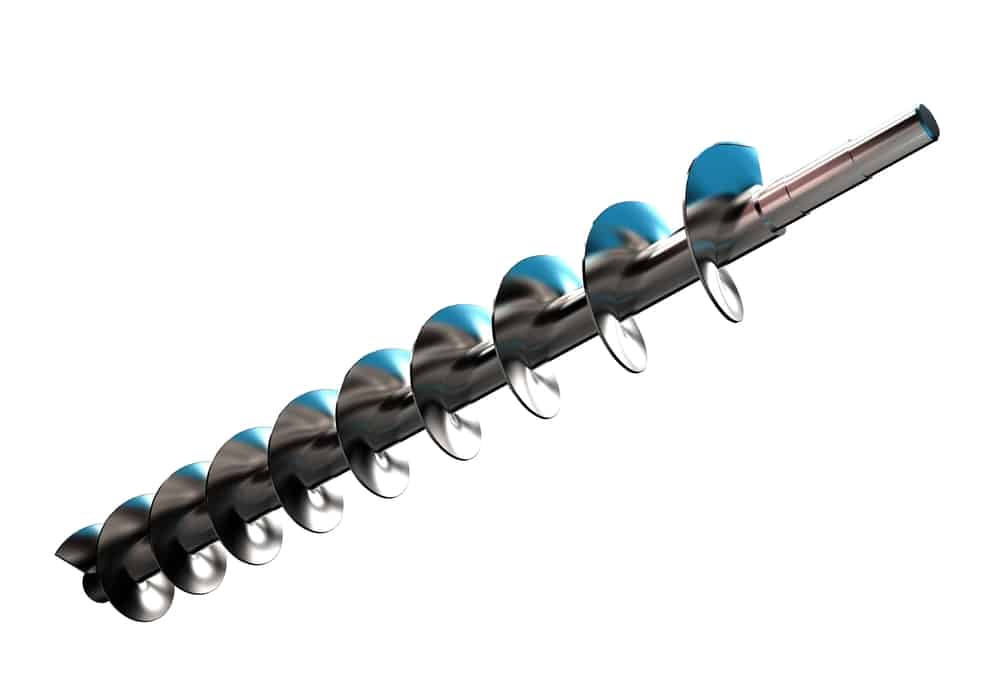

Stainless Steel Auger

Leave a CommentReinke & Schomann Inc. has been around for more than nine decades, and we have the capabilities and skills to manufacture custom metal products. One of these is stainless steel auger, a type of conveyor material. It can be used in a variety of applications for different industries.

Most of the time, some industries need stainless steel augers with specific applications to meet the needs of a particular industry. We can meet those requirements and work with you from design to end product.

What is a Stainless steel auger?

Stainless steel augers are a type of conveyor screw commonly used in the food-processing and pharmaceutical industries (water treatment equipment). However, it can also be used in different sectors for various applications.

The main advantage of using a stainless steel auger over other conveyor screws is that it is much more resistant to corrosion. Therefore, it’s not susceptible to rust since stainless steel is a metal that has 10% chrome, which makes it resistant to corrosion or contamination.

Additionally, it means that your equipment will last longer, and you won’t have to replace it as often. Additionally, since the screw is made of stainless steel, it is also easier to clean, which is vital in food-processing applications.

How do stainless steel augers work?

A spinning screw drags the material through the conveyor in stainless steel augers. A motor rotates the screw, pulling the material along with it.

The speed at which the screw turns will determine how fast the material moves through the conveyor. Additionally, the size of the screw will evaluate the capacity of the conveyor.

The angle of the screw can also be adjusted to change the direction of the material flow. For example, if you want the material to move horizontally, use a horizontal screw.

Advantages of stainless steel augers

Stainless steel augers are used in many industries for their specific advantages over other conveyor screws. Here are some of them:

- It is much more resistant to corrosion and rust, so your equipment will last longer.

- It is easier to clean since it is made of stainless steel.

- It can handle many different types of materials.

- Does not require paint or coatings to help prevent corrosion.

Common applications of stainless steel augers

Stainless steel augers are commonly used in the food-processing and pharmaceutical industries. However, you can also use them in different sectors for various applications.

Some common applications include:

- Conveying food products such as flour, sugar, spices, and grains

- Conveying pharmaceutical products such as pills, capsules, and tablets

- Conveying small metal parts such as screws, nails, and washers

- Material separation for water treatment plants and screw pumps.

Custom stainless steel augers by Reinke & Schomann

We have years of experience crafting custom stainless steel augers applicable to all types of use. Our team consists of professionals who can handle your specific requirements. Therefore, we always put quality first over quantity to meet the needs of your industry.

Stainless steel is a generally safe metal commonly used in the pharmaceutical and food industries. You can be assured that when you partner with us, we will create a product of the highest quality.

We manufacture stainless steel augers for various industries

Custom-made products are best if you want to maintain consistency. And we are fully equipped to deliver you the result you’re looking for.

Reinke & Schomann Inc. is your trusted manufacturer of stainless steel augers, and we strive to meet perfection. Request a quote now, and we’ll be happy to work with you.